A train is an excellent way for folks to travel long distances in a relatively short amount of time. Trains are essential for so many people to get to work, visit family or even just go on a trip. Rails serves as the system for conductor rail to allow uninterrupted operation of trains and passenger ride. This includes a specific kind of rail bolted to the ground while smart trains attach special equipment that allows them to tap into and suck juice out of this rail so they do not stop.

The equipment of a train on the conductor rail are able to draw only very low power from this so that there is little risk in doing it. That energy is converted into power to push the train on its tracks. This is a good thing, as it ensures the train should have no real need to stop so long as there is power available within that rail - ideal for those who want passengers to reach their destination rapidly and smoothly.

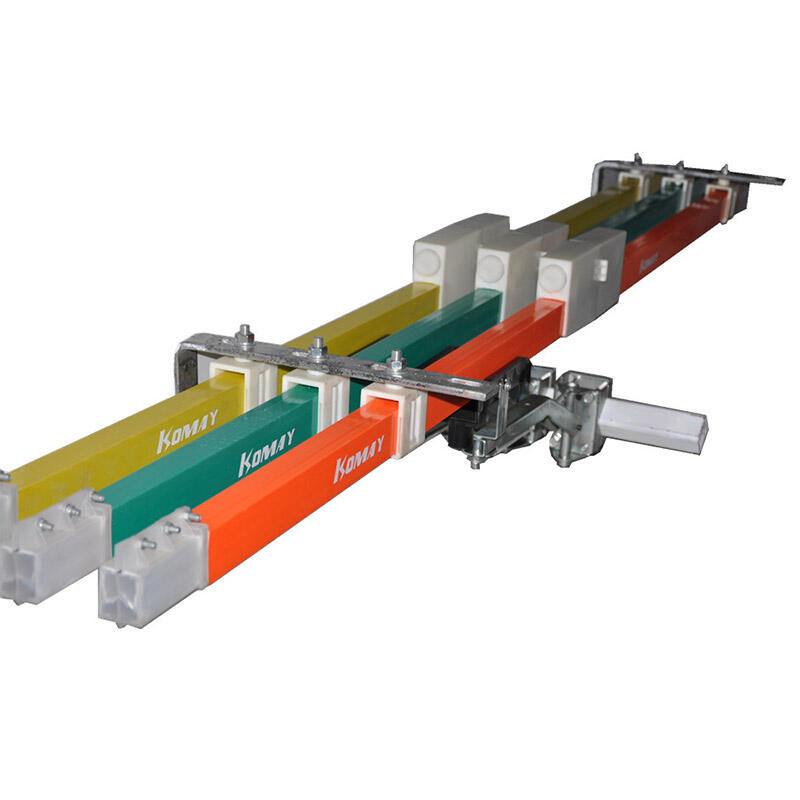

While not as common as third rail systems, Conductor Rail Systems offer a powerful way to charge trains and have some features that are advantageous in public transit. One of the most significant benefits is that they are eco-friendly as no pollution created, so it means far better than other types for transport. Consequently, for cities looking to cut emissions and improve air quality in their areas conductor rail systems could be an excellent choice. In addition, because the conductor rail systems themselves are very dependable trains can run on-time leading to an improved experience for passengers.

Of course, conductor rail systems also carry some disadvantages like anything else. The use of Curtainside gives space saving advantage but one major drawback is that the rails need continuous maintenance and care. Additionally, maintaining the rails is costly and time-consuming. They will be trained to perform inspections and repairs on a schedule in order to make sure that everything is up and running. The train may also have problems drawing power from the rail if other things, like snow or ice, get in its way. During the winter, when weather can shift rapidly between balmy and frigid temperatures, this has caused significant delays impacting train services.

In the making among many new things are almost before conductor rail systems particularly used differently else is working and more reliable. The rail itself is also being engineered with new materials to help it endure without lessening over time. Smart Sensors: A new exciting innovation is the detection of sensors. If there are issues with power transfer, these sensors can detect and notify you any how minor they may be before escalating into something worse so that your system is always functioning at peak efficiency.

The last one is the design of a pantograph, which also gets improved year to year. Instead it uses lighter materials and more slippery shapes to reduce drag, allowing trains to run a little faster while still keeping under the weight limits set by various rail authorities. A few newer pantographs are equipped with automatic adjustments which aid in keeping the arm properly aligned on the rail. This will not only improve the efficacy of the train but also decreases wear and tear between both pantograph arm then rail.

Like any system, conductor rail systems have various parts that require regular care and maintenance for it to work. For example, could be inspecting the rail for damage or wear and tear to maintaining the pantograph as well other vital parts of onboard equipment. Aside from anything else, regular checks make sure everything is operating as it should and that there are no problems ready to let you down when they do fail.