Have you been at a major construction site? And if you have, people are typically lifting heavy stuff high up on that monster which appears similar to this. What you see in this picture is a piece of equipment named crane In construction, cranes are vital machines that consist of a wide variety of parts working together for different purposes. Another essential thing to consider in a crane gets called the conductor bar. Today we are going to explore the world of crane conductor bars and why they play a critical role in keeping job sites both safe and productive.

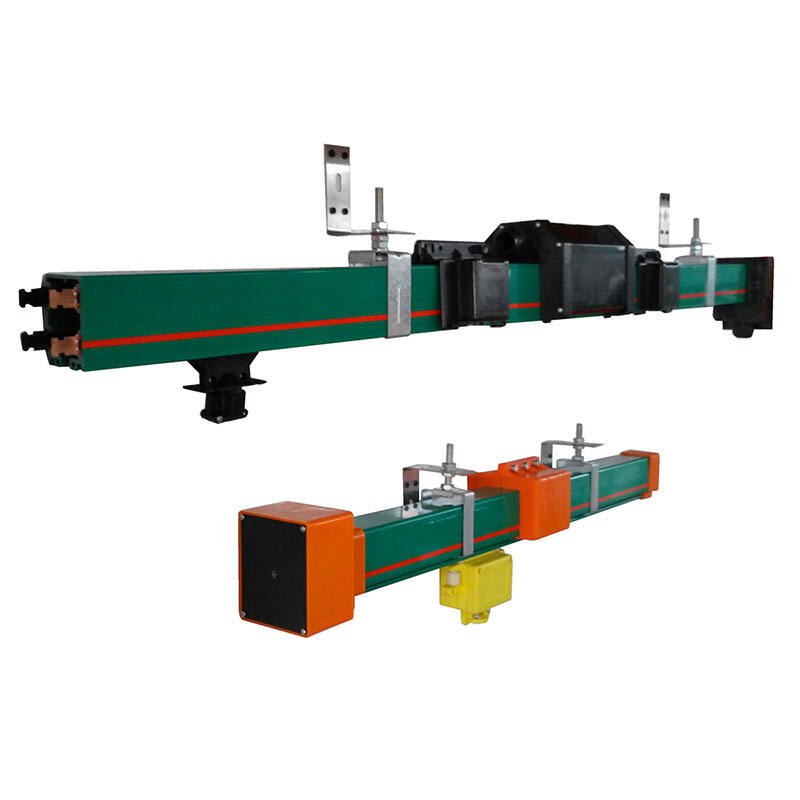

Crane Condutor Bar is a skinny, lengthy metallic strip that runs alongside the size of the crane. One of these is to supply the crane motor with electrical energy. This power assists the lifting crane to take and move heavy things safely. While using regular power cables, it is much easier to get shocked or experience a short circuit but crane conductor bars are safer than this. They are less likely to be damaged or get tangled as can often happen with other types of connection cables. The use of conductor bars prevents accidents and becomes a safe work environment for all.

Traditionally, crane operators have used ordinary electrical cables to provide the necessary electricity for their machines. But as technology got evolved with time, so were the designs of crane conductor bars. Modern conductor bars can withstand extreme hot and cold temperatures so they work in a variety of weather. In addition to this is a high quality, they are also incredibly strong and durable which reduces the likelihood of electrical faults occurring that in turn could pose risks for workers. Advanced Conductor Bars for Safer and More Productive Construction Sites

Laying of crane conductor bar is not a easy task. This requires a great deal of skill and understanding about cranes as well. That is why, it will be quite useful to have a professional team who knows the ropes of how all this work — especially when your crane and has type specific cable festoons. They know how to get the hook ups done properly Regular maintenance is crucial to ensuring that the crane conductor bar longevity, and operates with optimal efficiency. This means keeping an eye on the bars and solving a problem as soon as it pops up rather than waiting for everything to build.

In a construction zone, one of the most important things for which you need to take care is crane conductor bar. Cheap conductor bars are at risk of electrical risks and will most likely wear out faster compared to more premium choice. That in itself is a recipe for disaster. When you spend in the best crane conductor bars, after that your overhead will surely operate properly even though this raises a really weighty thing. Safety should always be of paramount importance in any construction site and what better way to ensure that, than by using the correct tools.

Link to: Future tech in crane conductor bars - how we build and construct things is changing Today, the conductor bars in use are cutting-edge materials which can work under extreme temperatures and support heavy loads and even survive earthquakes. These are long-lasting and can be used in almost all sorts of cranes. This versatility allows them to be used in all types of construction from custom homes, track housing and apartments. Latest technology not just makes the work-site safer but they also improve productivity.