What this means is that while overhead conductor systems are very important for us as they help in conveying electricity throughout a large number of regions across the globe, it thereby also exposes them to some major multifarious loads. These are the roads of electricity, carrying electrical power from places like power plants to where it is used in our homes and businesses. These systems will have to be intentionally designed, created(install) (and keep conducting). So, in this article we will discuss the issues that come with choosing how these systems are pieced and fit together; what must be taken care of whilst installing them (the dos); aspects of their upkeep which includes why your rolling garage door NEEDS a lil check up every now and then.;p And garden 'em up with some nifty thoughts.

OVERHEAD CONDUCTOR SYSTEM DESIGN 101

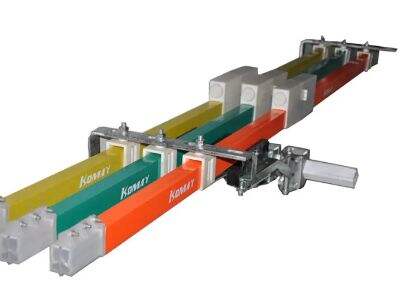

Parts will be chosen by the architects of an overhead Conductor Bar system. This includes selecting the right cables, poles and insulation…. These are the insulators which keep electricity secure from poles and wires. Organizations such as KOMAY create a selection of Wearables secure to use and also check out adhere ideal methods. Engineers developing such systems must take into account several important design considerations. They need to know everything leading the placement of distance between poles, size and weight limit of pole as well wind strength at that place. But you also have to find out how much electricity the system can transmit through. If large amounts of electricity are to be administered, then the conduit carrying it will require more bulk in order that they remain intact during travel along those wires.

Safety Overhead Conductor Systems: Order of installation

Important points in the installation of a conductor system overhead The workers who are concerned with servicing must first of all go through the area where it is about to operate and remove any things that may come in road during working. They may be trees, or signs, or some other obstructions […] Once that is done at hand the work crews gather all the necessary equipment as poles carrying conductor (the wires) including insulators and what else are basic tools. They also measure and flag poles for proper location. They also have to set the poles at different heights from ground and place them on whatever surface it is non silkie you provide some changes. With the poles correctly placed and aligned, Now they put insulators with other hardware stuff to finally fixing of wires. Crew safety come is first hence, they need to follow all the safety norms and protocols starting with from beginning recursively till end (An AA).

Best Practices for Healthy Overhead Conductor System Longevity

Proper maintenance is necessary for Overhead conductor rail system to last longer. Obligatory maintenance is also required with this. A great rule of thumb is this: leave the poles alone and everything that would harm a pole from pests, weathering effects to simply just aging. Wood posts, for example are prone to insect damage and rot if not properly treated. Yes, having the system regularly maintained is very important and that can include a good look at it as well as using heat cameras to attempt uncovering hidden problems. These things help us to find problems as early in the project cycle as is practically possible… before they become insurmountable roadblocks or worse a risk to life. This involves a cleaning of the system and replacing parts that are worn, fixing a broken wire. Every single one of these individual process guarantee wearing out and original functionality of overhead conductor systems for all previous years.

Importance of Regular Overhead Conductor Systems Inspections (optional):

Regular inspections are important because they allow workers to expose symptoms of harm. That includes searching for things such as rust, frayed wires or compromised insulators. KOMAY supply testing services to find key points of troubled conductor systems. They also allow you to better manage your systems, keeping them secure in the building and discovering problems while they are still easily managed. This way the manageable life of your system may get increased and nobody will be in danger due to any possibility or potential hazard. Program Inspections: Think of program inspections as the maintenance check-ups for those systems to make sure everything is doing what it's supposed to be and anything that might go wrong can head off at the pass.

Here at KOMAY

We innovate to develop the most forward thinking and dependable products that are necessary for safety overhead conductor rail design and maintenance. Something that makes for a particularly nice touch, is their use of a special composite material in the poles. These are two constituent materials (one is almost always cheaper than the primary and has better structural properties then conventional substances previously used. Many of them are also highly weather resistant, making it a better investment in the long run. This will also still move large parts of inspections off-line (with men in the loop only for exception processing) but raise dramatically quality assurance and safety.

Overall, overhead conductor systems are a crucial element in power distribution and serve as an efficient and safe means of transmitting electricity. This requires deep forethought + disciplined execution to design, build and nurture systems like this. AC16 order branded safety, as long as be evolved according to greatest procedures proven here; Follow designers KOMAY promises to provide a variety of all-new high-quality and advanced solutions for power distribution networks, which can thus continuously achieve safer and more sustainable infrastructure around the globe.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

BN

BN

MN

MN

KK

KK

KY

KY